HEAT RANGE

![]()

| HEAT RANGE | COLD | HOT | ||||

|---|---|---|---|---|---|---|

| BRISK | 8 | 10 | 12 | 14 | 15 | 17 |

| NGK | 10 | 9 | 8 | 7 | 6 | 5 |

| DENSO | 31 | 27 | 24 | 22 | 20 | 16 |

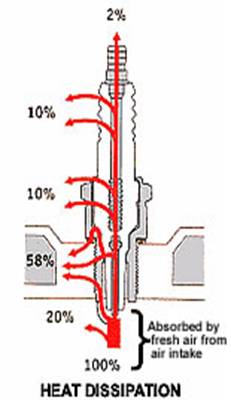

Heat range is the measure of how fast the spark plug tip dissipates combustion heat. It must do this in precise and controlled manner so the spark plug will:

- Stay cool enough to avoid pre-ignition and/or electrode destruction due to detonation.

- Run hot enough to burn off combustion deposits that would otherwise collect on the insulator tip and cause fouling that results in misfire.

- Adapt to specific engine characteristics and widely varying driving/load conditions.

Why is Heat Range Critical?

Two basic conditions for proper performance of a spark plug are given by sufficient electrical insulation between the center and ground electrodes and heat transfer from the parts of the spark plug projected into the combustion chamber. Both conditions are directly related.

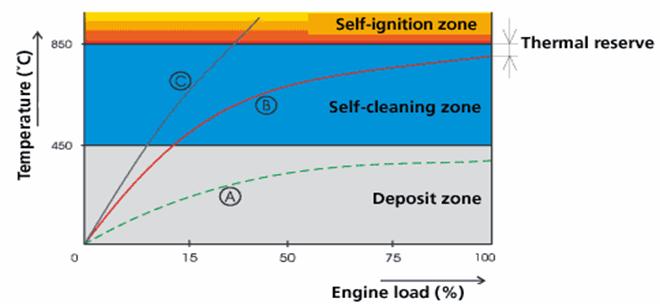

In order to ensure sufficient insulation between center and ground electrodes it is necessary, during operation, to keep the insulator tip (the part of the insulator projecting into the engine area) within an optimum temperature range.

Insulator tip temperature influence on the proper choice of spark plug heat range

A. Too cold spark plug for a given engine

B. Suitable spark plug for a given engine

C. Too hot spark plug for a given engine

If the insulator tip temperature drops into the so-called deposit zone, combustion deposits (carbon, non-combusted fuel, lubrication oil, impurities from the atmosphere) start to form on the insulator tip surface. A consequence of these combustion deposits on the insulator tip is reduction in electrical insulation resistance accompanied by failing ignitions and after a certain period of time even by a failure of the spark plug performance.

Providing a higher temperature of the insulator tip, no further combustion deposits are formed, but those already existing will not be burnt until the insulator tip temperature rises above 500 °C - the so-called self-cleaning zone. In this temperature range, no new deposits are formed and those existing will be burnt. The spark plug operates in an optimum manner.

Too high temperature of the insulator tip is undesirable. High temperature results in pre-ignitions of the air-fuel mixture and further compression of the mixture already ignited leads to high temperature, which can cause serious damage to the engine.

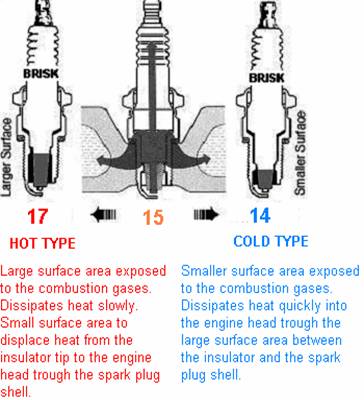

In order to achieve the correct temperature of the insulator tip for a given engine, the spark plugs are produced in various thermal values. The range of thermal values for BRISK spark plugs extend from the warmest to the coldest, namely 19, 18, 17, 15, 14, 12, 10 and 08.

"Hot" spark plugs remove heat from the combustion area relatively slowly. They have a longer insulator tip and they achieve a temperature higher than the deposition zone relatively fast.

"Cold" spark plugs feature a relatively short insulator tip and they remove heat from the combustion area quite fast, in order to avoid advanced ignitions.

The choice of a proper heat range is very important. But even a spark plug featuring a properly selected heat range, is influenced by the processes of fouling and self-cleaning of the insulator tip. The setting of combustion deposits on the insulator tip is caused by an imperfect combustion due to a "rich" air/fuel mixture. On the other hand, the combustion deposits previously set will burn if the insulator tip temperature rises above 500 °C.

Zones of fouling and self-cleaning zone depending on the air/fuel ratio and on the insulator tip temperature

| Zone of fouling with non-evaporated fuel | |

| Zone of fouling with dry combustion deposits | |

| Inert zone | |

| Self-cleaning zone |

Zone of fouling with non-evaporated fuel - this is the zone of the highest degree of fouling for spark plugs. The mixing ratio of fuel and air is very low in this case (rich mixture). Diffusion (atomization) of fuel is low and the fuel burns in its liquid state. Level of creation of combustion deposits is significant. In addition, the insulator tip is wet from the non-evaporated fuel. The decreasing insulation resistance of the insulator tip results in an occasional failure of ignition. Cold starts and frequent moving off from rest in cold weather will accelerate the fouling of the insulator tip.

Zone of fouling with soft deposits - vehicle engine run at idling speed or its low load can result in the setting of soft (dry) combustion deposits on the insulator tip, even if the fuel does not burn in liquid state.

Inert zone - in this zone, there does not occur any setting of combustion deposits on the insulator tip and there does not occur any self-cleaning either. No deposits set on the insulator tip surface even if the spark plug temperature drops below 500 0 C. The new spark plug does not feature any fouling and if a spark plug is fouled, it does not get cleaned.

Self-cleaning zone - The combustion deposits set in this zone on the insulator tip will burn and the insulation strength of the insulator tip will return to a common value. The shift into the self-cleaning zone generally takes place during acceleration and at higher speeds of the vehicle.

|

|

|

|

|

Fouling with non-evaporated fuel |

Fouling with dry combustion deposits |

Self-cleaning |

Determination of thermal value of a spark plug

While the engine is running, the spark plug is being heated to a certain temperature. The highest temperature can be detected at the insulator tip end. Thermal balance between the input and output of heat from the spark plug is determined by the value known as the spark plug heat range. An important parameter of this heat range is given by the so-called self-ignition value. It is measured by a special measuring engine by means of a gradual increase in the supercharging pressure up to the initiation of self-ignitions of the spark plug. The self-ignitions are indicated with the help of the ionization method, than they are processed by the control system with a feedback to the engine control. The thermal load is expressed by the IMEP (Indicated Mean Effective Pressure lb/in 2 ) units.

Determination of engine equipment with spark plugs

The equipment test of a particular engine is carried out with the help of special equipment making it possible to detect self-ignitions during an increase in spark advance in comparison with the original one, at a load of the engine. A part of the equipment tests is often formed by a starting capacity test carried out in a freezing chamber, as well as operation tests.